The Duty of Defoamers in Enhancing Product Quality and Performance

Defoamers offer as crucial ingredients that mitigate this problem, guaranteeing smoother manufacturing workflows while improving the aesthetic and useful features of the last products. The selection of the suitable defoamer can be critical to accomplishing optimum results, increasing crucial inquiries regarding formulation compatibility and efficiency metrics that merit additional exploration.

Comprehending Defoamers

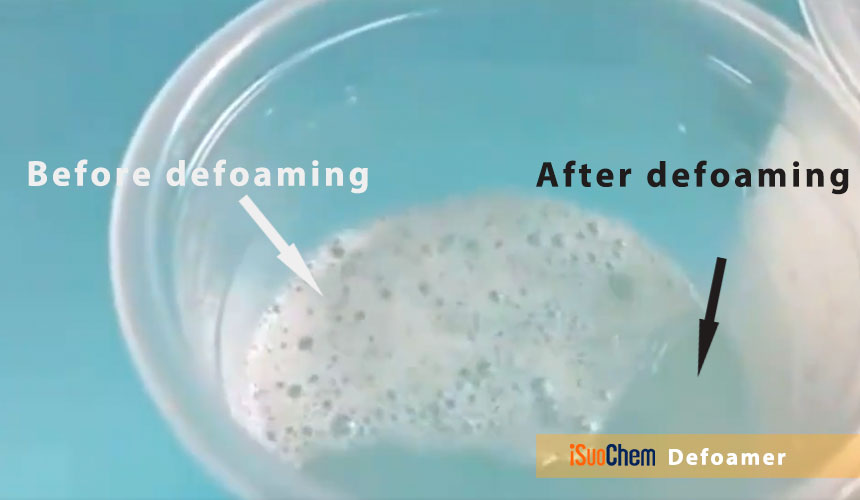

Recognizing the duty of defoamers is important for preserving product top quality across different sectors. Defoamers are chemical additives designed to prevent the development and decrease of foam in liquid systems, which can detrimentally influence processes such as blending, filling, and surface area tension. Frothing can lead to inadequacies, product issues, and jeopardized visual allure, making defoamers a vital component in manufacturing operations.

In commercial applications, defoamers assist to enhance item consistency and stability. The efficient use of defoamers not just guarantees smoother production procedures yet likewise contributes to premium product performance.

Additionally, the selection and solution of a defoamer should align with specific application requirements, such as compatibility with various other components, efficiency under differing temperature and pH problems, and potential governing restrictions. Ultimately, understanding defoamers' features and their importance in different formulas is vital for maximizing manufacturing and guaranteeing the best quality end items.

Types of Defoamers

Defoamers can be classified into several kinds based upon their composition and system of action. The key types include silicone-based, non-silicone organic, and not natural defoamers.

Silicone-based defoamers are amongst the most reliable, primarily because of their capability to spread out rapidly on the fluid surface area and interfere with foam formation. Their distinct chemical framework allows for exceptional security, making them appropriate for high-temperature applications and settings with differing pH levels.

Non-silicone organic defoamers, commonly made up of all-natural oils or fats, are valued for their biodegradability and lower toxicity. These are usually utilized in food and drink applications where safety and security and ecological impact are paramount.

Inorganic defoamers, which include compounds like talc or calcium carbonate, act by boosting the density of the liquid, thus minimizing foam security. They are often utilized in industrial processes where compatibility with other materials is not a worry.

Each kind of defoamer has unique advantages and restrictions, enabling customized services depending upon the particular foaming problems experienced in various applications. Recognizing these distinctions is vital for maximizing efficiency and accomplishing desired product quality.

Applications Across Industries

Numerous sectors take advantage of defoamers to enhance product quality and functional effectiveness. In the food and beverage field, defoamers are critical in procedures such as brewing and milk manufacturing to avoid foam formation, which can lead to inadequacies and product inconsistency. By regulating foam, producers can make sure better return and a more consistent product.

In the pharmaceutical industry, defoamers play an essential function in the solution of liquid drugs, where too much foam can hamper mixing and precise application. Their use aids keep the integrity of the formulations and assists in smoother production procedures.

The paint and coverings market additionally depends on defoamers to improve the performance of items during application. By lessening foam, these additives make sure a smoother coating and enhance the visual top qualities of the final item.

Advantages of Making Use Of Defoamers

While the application of defoamers differs throughout markets, their benefits regularly boost product quality and procedure performance. One substantial benefit is the reduction of foam formation during making procedures, which can or else result in production delays and inconsistencies in item top quality. By decreasing foam, defoamers allow a smoother flow of materials, facilitating extra reliable operations and decreasing the likelihood of tools breakdowns.

Furthermore, using defoamers can boost the appearance and texture of last items. In industries such as coverings, paints, and food handling, extreme foam can compromise the aesthetic looks and general quality, while the ideal defoamer application makes sure an uniform coating and desirable features. Furthermore, defoamers can add to set you back financial savings by lowering waste throughout production and maximizing making use of basic materials (defoamers).

Choosing the Right Defoamer

Choosing the best defoamer is important for enhancing manufacturing processes and guaranteeing product quality. The choice of defoamer affects not just the performance of foam control yet likewise the general performance characteristics of the final item. Variables to take into consideration consist of the sort of application, the chemistry of the formulation, and the environmental problems under which the item will be used.

Various sectors might need certain defoamer types, such as silicone-based, organic, or polymeric defoamers. Understanding the compatibility of the defoamer with the primary active ingredients is important to prevent adverse reactions that might endanger item stability. Furthermore, the defoamer's efficiency in various temperature levels and pH levels must be evaluated to make certain constant performance.

Checking the defoamer in small applications can offer beneficial insights right into its performance and suitability. Factor to consider of regulative conformity, especially in food, drugs, and cosmetics, is paramount in choosing a defoamer. Inevitably, a complete assessment of these aspects will certainly result in the option of a defoamer that not only manages foam properly but likewise boosts the quality and performance of the last item.

Final Thought

In conclusion, defoamers are important ingredients that significantly enhance item quality and performance throughout various industries. By properly reducing foam formation, these agents not only improve functional effectiveness yet additionally add to the aesthetic and functional stability of products. The calculated choice and application of defoamers cause set you back financial savings, maximized source usage, and boosted consumer satisfaction. Overall, the significance of defoamers in industrial processes can not be overemphasized, as they play a vital duty in attaining high-quality and consistent Extra resources outcomes.

Lathering can lead to ineffectiveness, product issues, and jeopardized aesthetic appeal, making defoamers a crucial part in making operations.